Smart burning solution

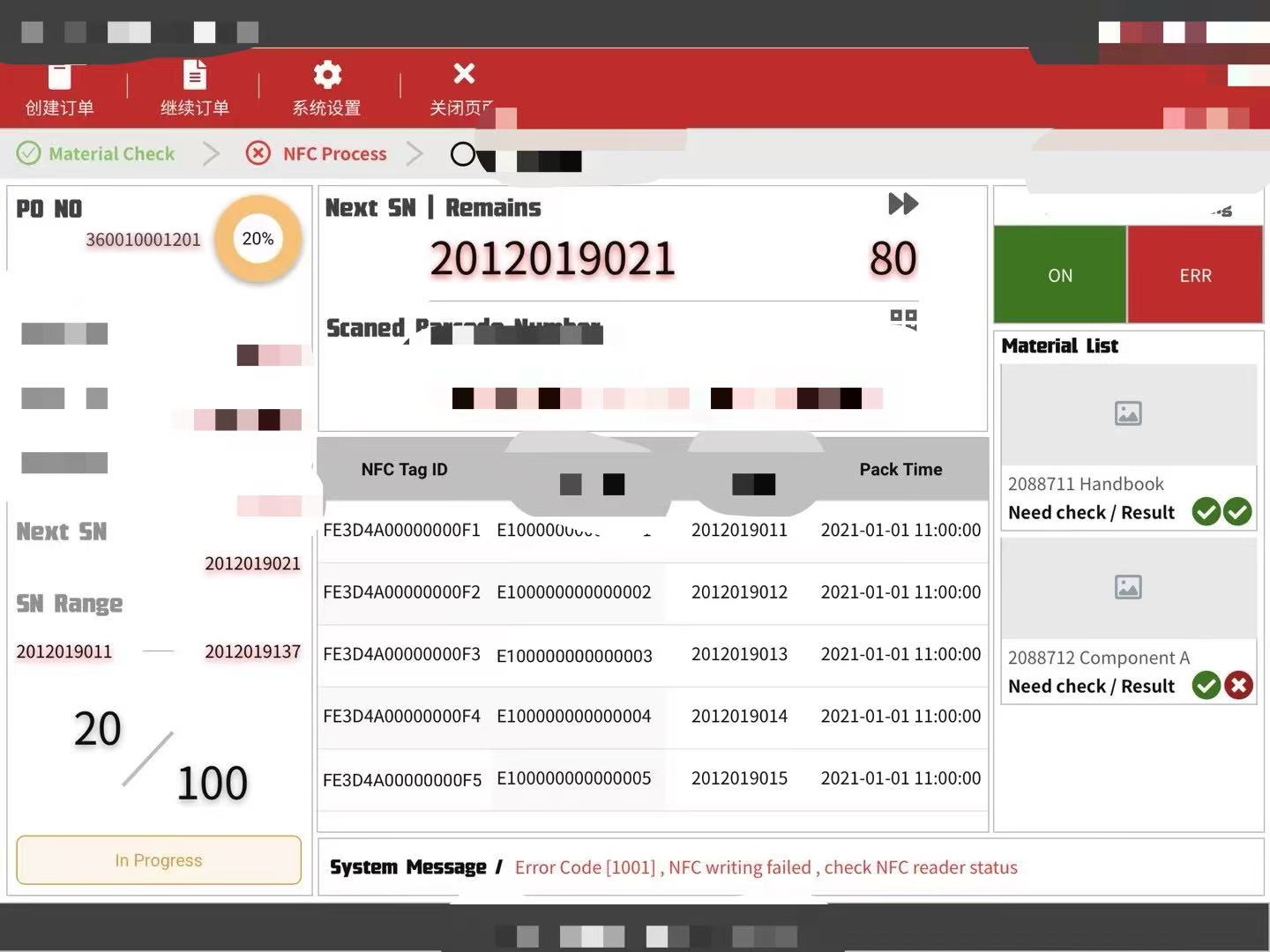

The purpose of the RFID intelligent burning solution is to provide customers with dynamic programming of parameters in the production phase, unique identification storage, and closed-loop management of production record tracing.

It is easy to integrate with third-party applications such as factory MES systems through exposed API interfaces.

- Control the uniqueness of tools.

- Easy identify of tool testing results.

- One piece flow of production.

- Dynamic tool parameters setting.

- PDA NFC function supporting in maintenance field.

- Tool information display via customer mobile application.

- Prevent counterfeiting.

- Wireless MCU communication.

- Data qualification from pre-station.

- Support different tag series.

- Adaption on metal surface driver.

- Dynamic driver parameters setting.

- Multiple burning client with one management platform.

- Wireless multiple production.

- Wireless MCU communication.

- Cross platform, Windows / Linux / MacOS / Android.

- Supporting all programing language.

- Just focus on your business, no need to know detail logic of reader or tag operations.

- Multiple ways of data input.

- Standard data format output.

- Continues of toolkit upgrading.

- Customized function supported.

- High quality and stability on base code.